Soldering Equipment

Simplicity, efficiency, precision and low cost.

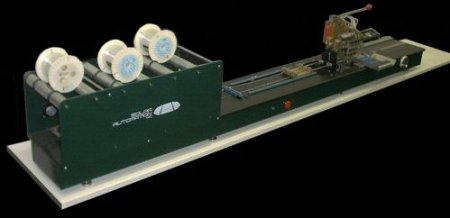

Combined Tabber/Stringer model CTS20

The CTS20 is a balance between automatic and manual operation. We designed it this way to make one-step machine tabbing/stringing available to the smallest module manufacturers.

Precision is built into the CTS20 tooling to insure top quality bonds, correct ribbon placement and cell position at the lowest possible cost.

New thin cells (180 micron) and lead-free solders are making hand soldering difficult. We studied the challenges in this tough combination and developed a heating system tuned to the new process.

If you are hand soldering strings and unwilling to pay the high price for automation, please read on. The Solar Automation CTS20 is made for you.

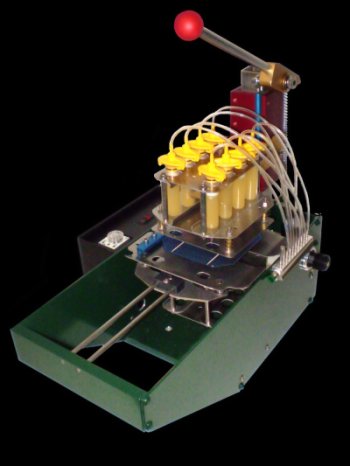

Flux Dispenser model SD2A

Using the least amount of flux and putting it exactly where it is needed are the basis for the SD2A design. There are many ways to get flux onto the bond area of the cell. It is the silver on the cell that needs the cleaning capability of flux. So we put it on the cell at the precise locations where the bonds are to be made.

The SD2A Dispenser uses 10cc syringes available from EFD. Each syringe places a measured dot of flux on the cell bus bar, both sides at once. For each size cell there is a syringe holder set, so that changeover from one cell size to another is quick and easy.

[ Home ] [ Soldering Equipment ] [ Parts and Service ] [ The Linear Module ] [ The Roof-Top Tracker ] [ The MicroFactory ] [ About Solar Auto ] [ Contact ]

Copyright Solar Automation, Inc. 2007