The MicroFactory

Today, the microfactory is taking shape, new shapes, all over the world. Products once produced in large centralized factories are undergoing redesign in order to be made in small, low-cost factories.

Tomorrow, The MicroFactory will revitalize communities everywhere and reinvent local commerce that is now devastated by the loss of manufacturing jobs.

What is a microfactory?

According to the National Academy of Sciences it is "a production facility whose output can be scaled up by the replication of identical facilities." It is a lot more than that.

A microfactory is a combination of robust, proven technology, efficient new tools and special people.

The Technology

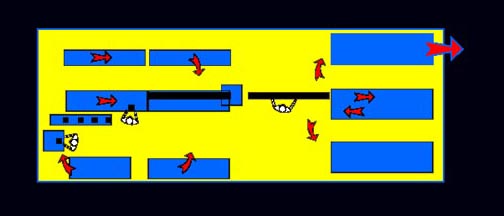

Thanks to continuous innovation in microelectronics, materials and processes, we have commercial off-the-shelf products today that turn the Industrial Revolution on its head. This means that there is a new way to make just about anything from simplified automobiles, to home construction components, to clothing and food. Here we address the production of photovoltaic modules, solar panels for generating electricity. To be competitive each potential product needs to be scrutinized for manufacturability, using methods called Design-for-Manufacture and Design-for-Automation.

The Tools

The tools for manufacture determine whether the factory is competitive and viable, whether it makes a profit or disappears. New kinds of tools are needed to revitalize or create an industrial base, to be competitive with factories everywhere regardless of labor costs.

The People

People will be needed who want to learn new skills. They will need to be comfortable with a range of tasks and be willing to own a piece of their own microfactory.

Solar Automation has developed a number of new low-cost machines, industrial equipment specifically designed for the photovoltaic microfactory. This new equipment is simple, uses a minimum amount of energy, yet makes solar modules at costs that are comparable with high-end automation.

Beyond that, the equipment can run on low voltage DC power so that the microfactory can operate efficiently and directly from its own solar panels. A solar-solar factory is born!

The new generation of factory equipment must be inexpensive. To do that we combine human skill with the right technology in a balance that derives the optimum from each. Machines are not required to do what people do better, and conversely. This translates into capital equipment and maintenance costs per unit, per year, that are lower than full-tilt automation.

It's all in the design.

[ Home ] [ Soldering Equipment ] [ Parts and Service ] [ The Linear Module ] [ The Roof-Top Tracker ] [ The MicroFactory ] [ About Solar Auto ] [ Contact ]

Copyright Solar Automation, Inc. 2007